The safety and compliance of faucets and shower systems in Central Europe is ensured by the most important world certification bodies.

Each certification bears witness to the exclusivity and uniqueness of each product, as well as CEIBS' will to ensure that its customers meet the highest quality standards on the market.

Zhongou sanitary ware has established a good reputation among its peers around the world. As of now, Zhongou Company has customers from 80 countries and regions, covering products from cities

to rural areas.The company's products have a dual nature, namely usability and artistry. When you walk into the kitchen or bathroom, your eyes will shine and your spirit will be refreshed.

The product design is humanized, and the installation is particularly simple, labor-saving, and cost saving.The company's products have undergone rigorous testing to ensure that 100% of the products delivered to

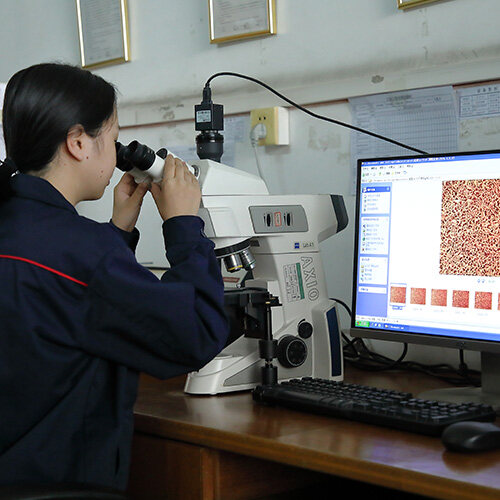

customers are qualified.The company has advanced manufacturing centers and precision testing instruments, including high-precision machine tools, punching machines, automatic polishing machines,

spectrometers, thickness gauges, hardness gauges, metallographic microscopes, etc.

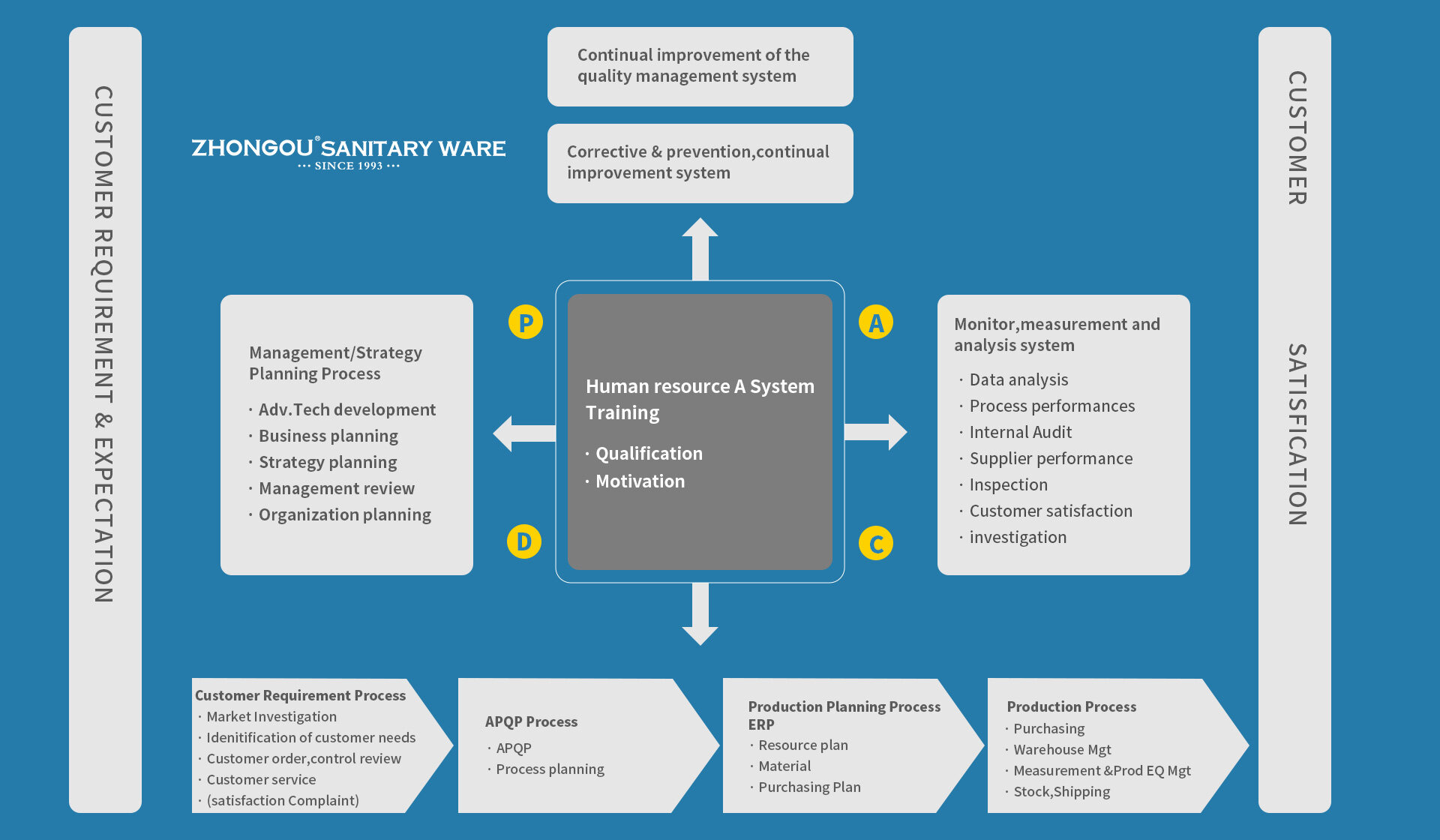

ZHONGOU PROCESS-ORIENTED

QUALITY MANAGEMENT SYSTEM

The quality of ZHONGOU products is assured by external certification according to the internationally recognized ISO 9001 quality management system standard.

ZHONGOU develop process-oriented QMS to identify and meet needs of customer requirement and expectation in an effective and efficient manner to achieve competitive advantage.